Categories: Capabilities, Software, Cyber, and Cloud Computing, Systems Engineering, National Security, Cabaniss

Infrastructure Matters: The Hidden Challenges Behind America’s Semiconductor Ambitions

- Alexandria, VA | August 26, 2025

As Christian Cabaniss, military operations analyst at Systems Planning & Analysis (SPA) and USMC Col Ret, notes, “We often imagine that if a policy is written and the budget is allocated, the work is done. But semiconductor manufacturing doesn’t happen in isolation. It’s dependent on a massive, often underappreciated ecosystem of infrastructure.”

Semiconductor Chip Series

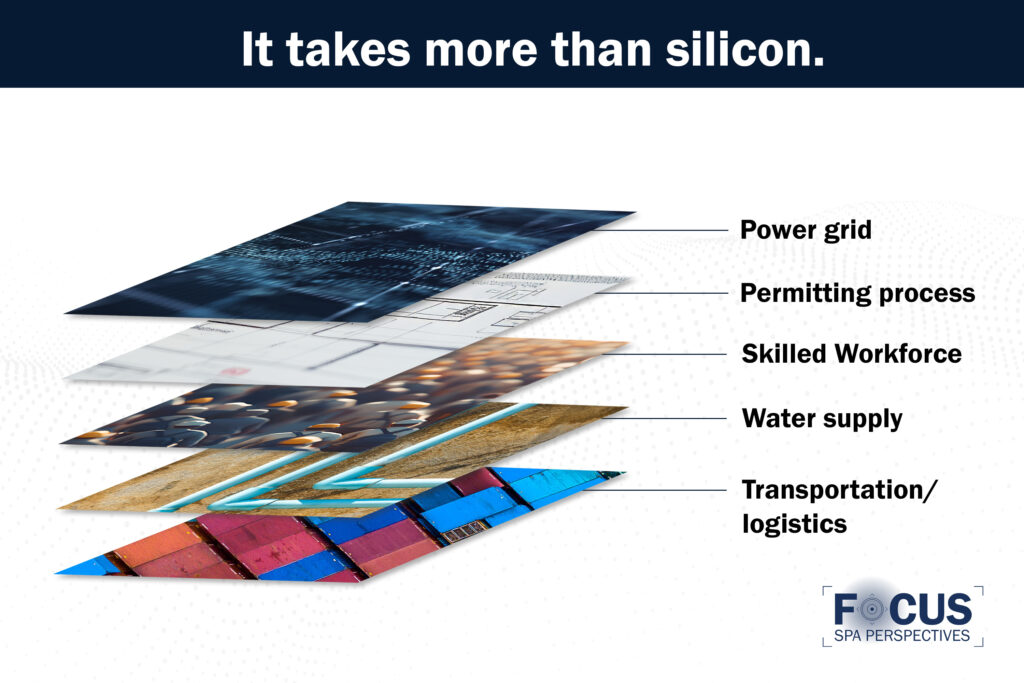

A state-of-the-art semiconductor facility may be a marvel of modern engineering, but it cannot function without an equally sophisticated support system. This includes stable and abundant electricity, skilled workers, specialized suppliers, and robust transportation networks. Every part of that system introduces potential delays and bottlenecks.

One of the least discussed yet most significant challenges is power. As Cabaniss points out, “The fab itself might take five to seven years to build, but connecting it to the necessary power grid infrastructure could take even longer. In some areas, it could take decades.”

This isn’t just about plugging in a new factory; it involves building or upgrading power generation, transmission, and distribution lines. These efforts often require dozens of permits from multiple federal, state, and local agencies, each with its own timeline and approval process.

The Power Challenge

The mismatch between semiconductor ambitions and electrical infrastructure is already visible. Take Northern Virginia, for example. It’s home to a massive concentration of data centers, many of which support global internet traffic. Data centers alone place enormous strain on regional power supplies. Add high-tech fabs to that equation, and you begin to see the scale of the challenge.

“

“In some cases, we’re talking about needing 50 or 60 different permits to build the transmission capacity necessary to power one site. And those approvals could take 15 to 20 years.”

Permitting delays are another substantial hurdle. Modern infrastructure projects often stall not for lack of resources, but because of the complex patchwork of regulations governing environmental impact, land use, and utility coordination. These processes are necessary, but without reform and streamlining, they will undermine any serious attempt to build resilient, domestic chip-making capacity.

“

Part of that commitment means recognizing that bringing semiconductor manufacturing home is not simply a matter of funding a few factories. It’s about rebuilding an entire industrial base and the physical and human infrastructure that supports it. And it means coordinating federal, state, and local efforts—no easy task given the fragmentation of regulatory and funding authorities.

- Streamline permitting. Federal leadership is needed to simplify and accelerate permitting for critical infrastructure tied to semiconductor production.

- Expand infrastructure investment. Funding for power generation, transmission, and site preparation should be tied directly to semiconductor initiatives.

- Invest in workforce development. Partnerships between industry, technical schools, and government must ensure a steady pipeline of skilled workers.

- Coordinate across government levels. Local, state, and federal agencies need shared objectives and aligned incentives to avoid working at cross purposes.

Subscribe now so you won’t miss the conclusion to this series. We respect your privacy and inbox, sending no more than one email per week.

Related Posts

We invite you to subscribe and stay informed. Never miss an update as we continue providing the rigorous insights and expert analysis you rely upon to protect and advance our national security.